The light of quality and civilization shines the world!

Products Center

Products Center

Stone Crusher

Stone Crusher

Grinding Mill

Grinding Mill

Optional Equipment

Optional Equipment

Mobile Crusher

Mobile Crusher

Knowledge Hall

Knowledge Hall

Crushers FAQ

Crushers FAQ

Grinding Mills FAQ

Grinding Mills FAQ

Mining Equipments

Mining Equipments

Solution

Solution

Stone Crushing

Stone Crushing

Sand Making

Sand Making

Ore Processing

Ore Processing

Grinding Plant

Grinding Plant

Construction Building Material

Construction Building Material

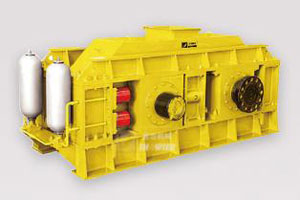

Roller crusher

Roll crusher is suitable for medium and fine crushing of materials with medium hardness, such as the limestone, slag, coke and coal, which are used in cement, chemical industry, electric power, metallurgy, building materials, refractory materials and other industry departments. Roller crusher mainly consists of roller, roll wheel support bearing, pressure and adjusting device and actuating device.

Type of Roller Crusher

?Roll crusher can be classified into Double roll crusher, four-roller crusher and toothed roller crusher.

?Roll crusher can be classified into Double roll crusher, four-roller crusher and toothed roller crusher.

Double roll crusher

This series of double roll crusher mainly consists of roller, roll wheel support bearing, pressure and adjusting device and actuating device.

Adjustment of discharging grain size: there are wedge or gasket adjusting device between the two rolls. Adjustment bolts are on the top of the wedge device. When the adjustment bolts pull the wedge block up, the wedge block make movable roll leave fixed pulley so that the interval between two rolls is larger and the discharging grain size is larger. When the wedge block is down, under the role of retainer spring, the movable roll will come near the fixed pulley so that the interval between two rolls is smalled and the discharging grain size is smaller. Gasket adjusting device can adjust the discharging grain size by increasing or decreasing the number of gaskets or thickness. When the gaskets are added, the interval between two rolls is larger and when the gaskets are reduced, the interval between two rolls is smaller and the discharging grain size is smaller.

Toothed roll crusher

Toothed roll crusher features high crushing ability. The distance limited type hydraulic coupler combines the electromotor and speed reducer to prevent power overload. Sensor features overload protection, which is safe and reliable. The intervals between toothed rollers are adjusted by hydraulic pressure. Toothed roll bearings are lubricated concentratedly. The tooth shape is optimization design. Pull and shear do chosen crushing. The toothed roller crusher features high efficiency and low energy consumption and it can produce the uniform grains. The toothed roller crushers are classified into two series, double toothed roller crusher and four toothed roller crusher. Double toothed roller crusher is mechanical spring type(2PCM) and this type crusher can be equipped with thick teeth roller or medium teeth roller respectively, according to the material properties and requirements. Four toothed roller crusher is the combination of two sets of double toothed roller crushers.

Roll crusher operations

- In order to ensure maximum output of the roll crusher , the feeding materials must be uniformly distributed on the full length of the roller.

- Discharge opening should be checked at fixed period to see whether there is blocking phenomenon. Before the motor stopped working, the feeding materials should be stopped at first. When the materials blocks are fully dropped down and the roller becomes empty rotation, the motor can be stopped.

- If the feeding materials are not uniformly distributed on the full length of the roller, the roll surface will be quickly worn and each point is worn in different level. For this reason, annular groove will be formed so that the normal crushing work is damaged and the grain sizes of crushed products are not uniform. Therefore, apart from the roller crusher that is used for coarse crushing, the medium roller crusher and fine roller crusher are equipped with feeding machine to ensure the feeding continuous and homogeneous. What's more, the length of feeding machine is same with the roll length so that the feeding materials can be uniformly distributed along the direction of roller length.

- Reasonable maintenance and correct operation of roller crusher can ensure long-term and continuous work and reduce stop time. Only normal management and checking the normal work of the roll crusher every rock can the stoppage be prevented to ensure the roller crusher work continuously.