The light of quality and civilization shines the world!

Products Center

Products Center

Stone Crusher

Stone Crusher

Grinding Mill

Grinding Mill

Optional Equipment

Optional Equipment

Mobile Crusher

Mobile Crusher

Knowledge Hall

Knowledge Hall

Crushers FAQ

Crushers FAQ

Grinding Mills FAQ

Grinding Mills FAQ

Mining Equipments

Mining Equipments

Solution

Solution

Stone Crushing

Stone Crushing

Sand Making

Sand Making

Ore Processing

Ore Processing

Grinding Plant

Grinding Plant

Construction Building Material

Construction Building Material

Home>Solution>Grinding Plant>Coal Crushing and Screening>Coal screening process

Coal screening equipment

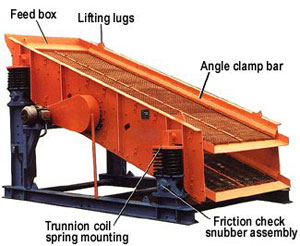

There are a variety of screening machines, and they can be divided into laboratory sieve set screen and industrial screen according to their usages. In the ore preparation plant, the fixed screen, scrolling screen and vibrating screen are among the most commonly used screens in the crusher plant. Major factors that may impede screening efficiency include material properties (granularity, viscosity and shape), equipment structure and operation conditions.

Screening process

The screen will carry out mechanical screening for the mixture of various granularities, and grade the materials by the sizes of the screen holes. Screening is a crucial part in the crushing process, aiming at improving crushing efficiency and controlling the product granularity.

The screen will carry out mechanical screening for the mixture of various granularities, and grade the materials by the sizes of the screen holes. Screening is a crucial part in the crushing process, aiming at improving crushing efficiency and controlling the product granularity.

Coal screening process

1. Preparation screening (pre-screening): As for crushing, preparation screening aims at separate materials of qualified granularity from coal lumps that need to be crushed before the crushing process.

The procedure could avoid over-crushing of materials. As to the beneficiation process, preparation screening is needed to group the raw coal into various grades because all coal beneficiation methods have their specific granularity requirement. Without pre-screening, the beneficiation efficiency would be significantly reduced.

2. Inspection screening: The process follows the crushing of materials, in which the screen will sort out materials that fail to meet the granularity demand and return them to the crusher for further crushing. The process could ensure the granularity of products. The most commonly used coal crushers include Jaw Crusher, Hammer Crusher and Impact Crusher.

3. Final screening: The process will screen the products by their granularity, and the products are coal products that will be directly supplied to the users.

4. Dehydrated screening and desZENITH screening.

5. Dense medium disposing screening.

6. Selective screening: Selective screening is a process in which the coal will not only be graded by its granularity but also its quality.

7. Coal slime recovery: The process is adopted in the dehydration of coal slime and tailings. The equipments in the process include jump titanium machine and condenser.

Factors that impede influencing screening efficiency:

1. Granularity. The closer the material granularity is to the threshold diameter, the harder it will be to separate the materials.

2. Humidity ratio. When the humidity ratio of the material increases, the material will be more cohesive, thus increasing the risk of forming a bulk or blocking the screening holes.

3. Shape and density. If the particles is too small or has excessively low density, they can hardly pass the screening process.

4. Screening plant parameters.