The light of quality and civilization shines the world!

Products Center

Products Center

Stone Crusher

Stone Crusher

Grinding Mill

Grinding Mill

Optional Equipment

Optional Equipment

Mobile Crusher

Mobile Crusher

Knowledge Hall

Knowledge Hall

Crushers FAQ

Crushers FAQ

Grinding Mills FAQ

Grinding Mills FAQ

Mining Equipments

Mining Equipments

Solution

Solution

Stone Crushing

Stone Crushing

Sand Making

Sand Making

Ore Processing

Ore Processing

Grinding Plant

Grinding Plant

Construction Building Material

Construction Building Material

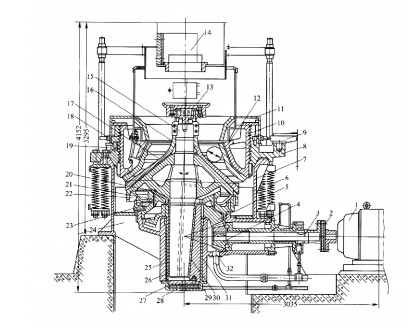

Cone Crusher operation and maintenance

Cone crusher is the fine crushing machine used in stone quarry plant, it has two types: short-head type and standart cone crusher.

Crushing cavity of Cone Crusher

Crushing cavity of Cone Crusher must adapt to the max feeding size. The max feeding size is about 80% of feeding mouth width. If the feeding mouth width is to large, the feeding materials can not be crushed in the upper of the crushing cavity and accumulate in the bottom of the crushing cavity. At this time, the crusher is overloaded and the production quantity is reduced. Generally in crushing cavity, it is reasonable that the large grains in feeding materials will be crushed 4 or 5 times then be discharged out of the machine. If the feeding mouth width is small, when the scaleboard is worn the crushing cone is adjusted upwards, the feeding mouth width is reduced, the large blocks are stuck and can not come into the crusher. The correct design is that: in all scaleboard working time, the large blocks can come into the crushing cavity and total power consumption is a little lower than motor power rating with little fluctuation.

Crushing cavity of Cone Crusher must adapt to the max feeding size. The max feeding size is about 80% of feeding mouth width. If the feeding mouth width is to large, the feeding materials can not be crushed in the upper of the crushing cavity and accumulate in the bottom of the crushing cavity. At this time, the crusher is overloaded and the production quantity is reduced. Generally in crushing cavity, it is reasonable that the large grains in feeding materials will be crushed 4 or 5 times then be discharged out of the machine. If the feeding mouth width is small, when the scaleboard is worn the crushing cone is adjusted upwards, the feeding mouth width is reduced, the large blocks are stuck and can not come into the crusher. The correct design is that: in all scaleboard working time, the large blocks can come into the crushing cavity and total power consumption is a little lower than motor power rating with little fluctuation.

Particle size characteristics of feeding materials

Particle size characteristics of feeding materials are also important. In the feeding materials, large grains and small grains should be according to a certain proportion in the mixture. The fine grain material whose size is lower than the discharging mouth width will be screened out by the prescreening. Prescreening work in quite important for fine crushing period, or the power consumption and abrasion will be increased and the production will decline.

Cone Crusher discharging mouth

The adjustment of Cone Crusher discharging mouth. The fine crushing Cone Crusher in concentrating plant, should bave smaller discharging mouth so that the more products with fine grain size can be got, the Ball Mill productivity can be improved and the grinding cost can be reduced. So in accordance with the worn condition of the crusher scaleboard, the operating workers must adjust the discharging mouth at any time to ensure the particle size.

Several Cone Crushers are set in fine crushing period. When the feeding materials are not enough, one or several fine crushers should be turned off. And all the fine crushers must not be working in inadequate load circumstances.

When using super fine scaleboard, the minimum that can be adjusted by discharging mouth depends on several factors, such as machine stress, scaleboard material qualitative, material friability, moisture content, abradability, scaleboard shape. The minimum should be ensured prudently. When some materials have high moisture, if the discharging mouth width is too small, the materials will be adhered near the discharging mouth and this phenomenon is called pressure brick or reunion. At this time, crusher stress increased sharply, machine is overload and insurance device began to work so that normal crushing work can not start. The minimum width that can be adjusted by discharging mouth depends on the specific conditions, which is between 2.5 and 9.5 mm.

Spring force plays an important role on the operation of the Cone Crusher. New series crushers working situation in our country mines is that: cone rusher usually is installed in concrete foundation. When installed on the top floor of workshop or the mobile crusher, the Cone Crusher with motor frame can be installed on floor or vibration isolation spring of vehicles.